Introduction

Did you know? Among the physical properties of paper, grain direction is one of the most overlooked—but that doesn’t make it any less important. So what exactly is it, and why does it matter? In this article, you’ll learn what paper grain direction is and how to identify it easily. If you’re curious, keep reading!

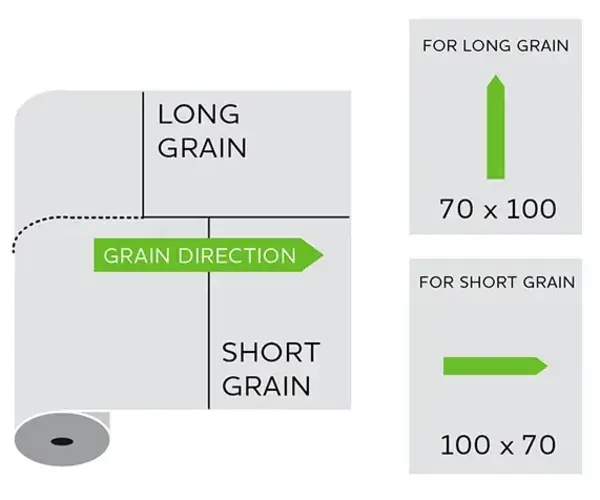

What is Grain Direction in Paper?

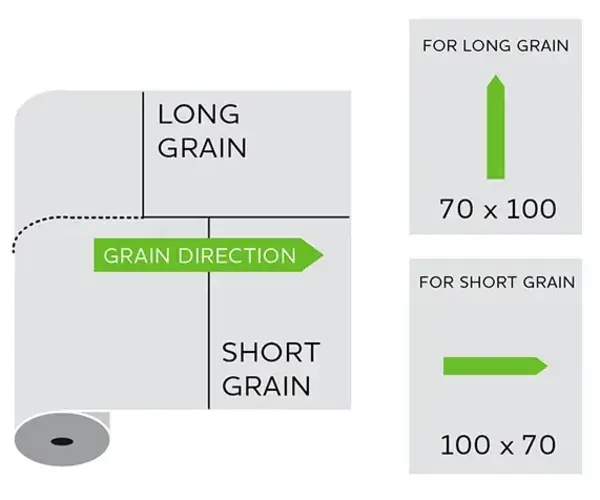

Grain direction refers to the alignment of fibers within the paper. It's also commonly called paper orientation or fiber grain. During machine-based papermaking, pulp is spread onto a moving mesh screen. The motion of the screen and the flow of the pulp cause the fibers to align mostly in the direction the machine is moving. This creates a consistent grain direction.

However, grain direction isn’t present in hand-made paper. Hand papermaking uses a stationary screen, and the pulp is shaken manually to drain the water. This process allows the fibers to spread randomly with no dominant alignment—so there is no grain direction.

7 Easy Ways to Find the Grain Direction in Paper

Let’s say you have a sheet of paper that’s 80x110 cm. The grain may run parallel either to the shorter side (80 cm) or the longer side (110 cm), resulting in two possible grain directions. So how can you tell which is which without special tools? Here are seven simple methods:

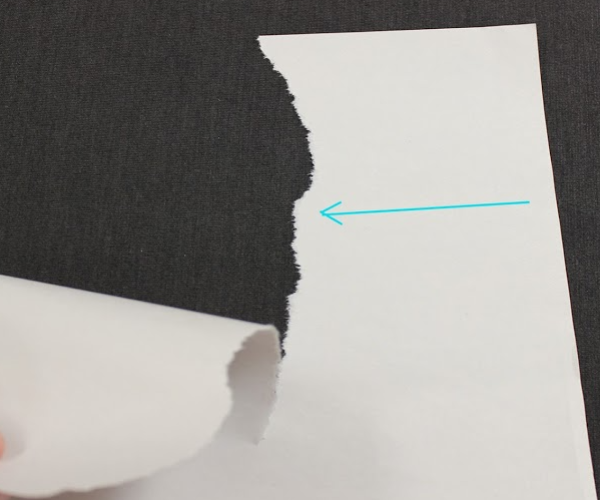

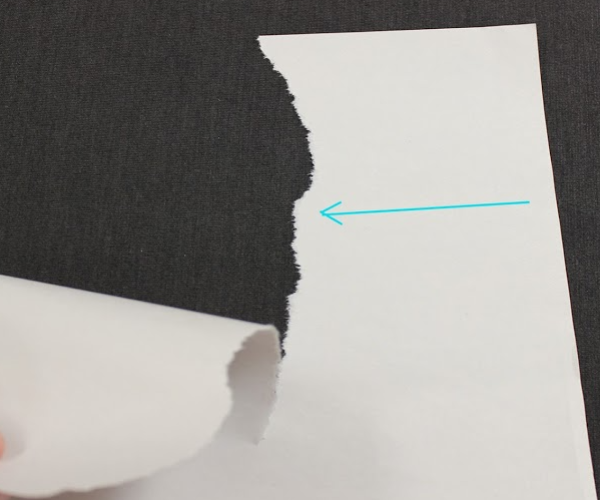

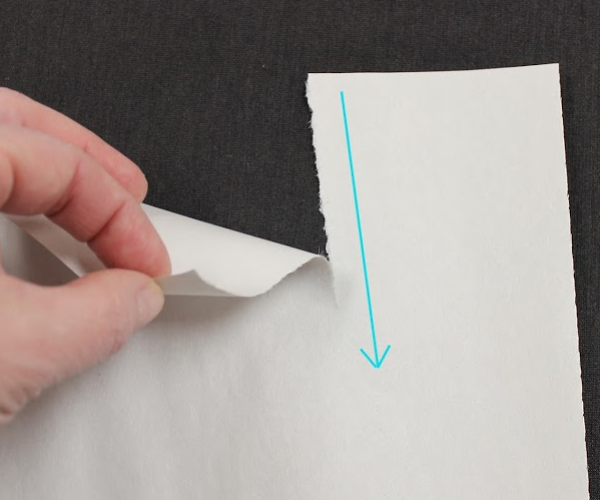

Tearing method

This is the most intuitive way. Tear the paper gently in opposite directions with both hands. If the tear is straight and clean, you’re tearing along the grain (long direction). If the edge is rough or wavy, you’re tearing across the grain (short direction). This method is quick and requires no tools.

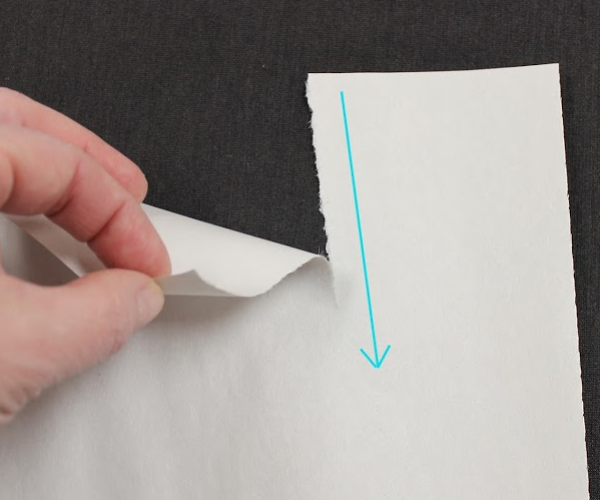

Pulling Method

Take the paper and pull firmly on two opposite sides. If it tears easily, you’re pulling across the grain. If it resists tearing, you’re pulling with the grain. This works because paper is stronger along the fiber direction.

Hand-Holding Method

Cut two strips of paper (about 100mm x 10mm) from different directions. Hold one end of each strip and let the other end hang freely. The strip that bends or droops more is cut against the grain (cross direction). The one that stays straighter is cut with the grain (machine direction).

Flip-Bend Method

This method works well for a stack of paper. Try bending a stack lightly from different edges and release. The edge that springs back firmly is the cross-grain edge. The one that feels looser or doesn’t snap back tightly is the long-grain edge. Printers often use this trick for quick checks.

Water Drop Method

Place the paper on a flat surface and put a drop of water on it. If the paper is uncoated, the droplet will spread into an oval shape. The long axis of the oval points in the grain direction. This happens because water spreads faster along the fibers.

Water Method

Tear a small square or circle of paper and wet it. As the paper absorbs water, it will start to curl. The side that curls inward is the cross-grain direction. The flatter side is the grain direction. This makes fiber expansion easy to see.

Nail sliding method

Gently scratch the surface of the paper with your nail in two perpendicular directions. If one direction feels smooth and the other creates a wavy or rough texture, the rough direction is across the grain. This method is useful when you can’t damage the paper.

Wrapping Up

Now you know how to find the grain direction in paper using simple methods. But why does it matter? Grain direction affects print quality, folding, binding, and even packaging performance. We’ll cover that in the next article. If you’re looking to buy paper, feel free to get in touch with us at Golden Paper. We’d love to help you find the right materials for your project!

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id

.webp)