Introduction

In packaging and labeling applications, synthetic paper self-adhesive labels are widely used in beverages, daily chemicals, food packaging, logistics, and industrial identification. However, bubbling after application remains one of the most common quality issues. Label bubbles not only affect product appearance but may also weaken adhesion strength and damage brand image. Understanding the root causes helps buyers reduce complaints and avoid unnecessary losses.

Uneven Adhesive Coating During Production

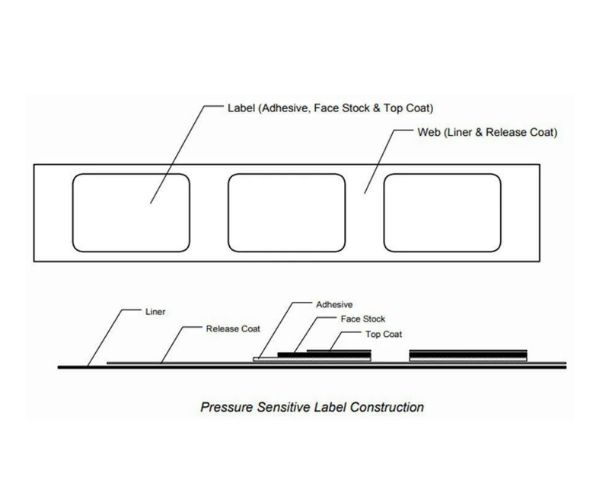

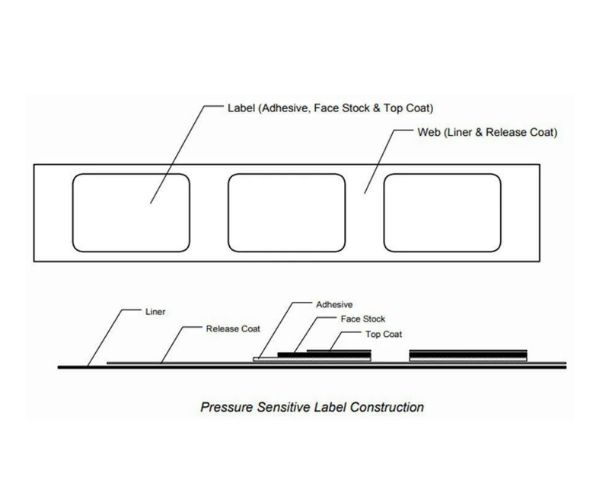

Self-adhesive label paper is typically composed of three core layers: printing layer (face stock), adhesive, and release liner. From a manufacturing perspective, it may include coating layer, face material, pressure-sensitive adhesive, silicone release coating, base paper, and back printing.

If adhesive coating is not evenly applied during production, the adhesive layer thickness will vary across the surface. When such labels are applied, areas with insufficient adhesive may fail to fully bond to the substrate, trapping air between the label and the object surface. Over time, these air pockets appear as visible bubbles.

This issue originates from coating process instability, adhesive viscosity control problems, or drying inconsistencies.

To avoid this type of bubbling, buyers should choose high-quality synthetic paper self-adhesive labels from manufacturers with stable coating lines and strict adhesive weight control. Material quality is the first control point in bubble prevention.

Insufficient Pressure from the Labeling Machine

In automatic labeling systems, key components include the unwind wheel, buffer wheel, guide roller, drive roller, rewind wheel, peeling plate, and pressure roller.

During operation, a sensor triggers the drive system. The roll label remains under tension, and when the release liner passes over the peeling plate, the label separates due to its inherent stiffness. At this moment, the product surface is positioned beneath the label, and the pressure roller applies force to bond the label evenly.

If the pressure roller has insufficient pressure settings, poor structural design, or alignment deviation, the label may not fully contact the surface. Small air gaps remain between the adhesive and substrate, eventually forming bubbles.

If bubbling occurs during automatic labeling, it is necessary to contact the labeling machine manufacturer to recalibrate pressure settings, inspect roller alignment, or optimize structural components. Proper mechanical pressure is essential for achieving bubble-free synthetic paper label application.

Careless Manual Labeling

Synthetic paper labels are generally flat, but due to adhesive tension, they may curl slightly after being peeled from the release liner.

During manual application, if the label is pressed down all at once without smoothing from one edge to the other, air can become trapped beneath the surface. This leads to wrinkles or bubbles, similar to applying a screen protector to a mobile phone.

Correct manual labeling technique involves starting from one side and gradually smoothing the label across the surface to ensure uniform contact.

Although manual labeling is not technically complex, lack of attention to detail can still cause bubbling. With proper application technique and stable material quality, this issue can be completely avoided.

From Material Control to Process Optimization

Bubbling in synthetic paper self-adhesive labels generally originates from three areas:

Adhesive coating defects during production

Insufficient pressure or structural issues in automatic labeling machines

Improper manual labeling technique

For packaging factories, printing companies, and overseas buyers, solving the bubbling issue requires both material evaluation and application process control.

High-quality synthetic paper label materials combined with correctly adjusted labeling equipment ensure smooth adhesion, strong bonding performance, and stable long-term application.

Conclusion

Synthetic paper self-adhhesive label bubbling is not a random issue. It is usually the result of material defects or application process problems. By selecting reliable synthetic paper label suppliers and ensuring proper labeling pressure and application technique, businesses can significantly reduce quality complaints and improve final product presentation. If you are sourcing synthetic paper self-adhesive labels and want stable adhesive performance with minimal bubble risk, working with an experienced manufacturer is essential. Golden Paper provides mature production control and consistent quality to support long-term cooperation.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id