Introduction

In the papermaking industry, the bulkness of paper is a key indicator that affects not only its appearance, texture, and printing performance but also production costs and overall quality. For different types of paper — whether for publishing, printing paper, or packaging paper — the right level of bulkness ensures better stiffness, higher opacity, and a more pleasing tactile and visual effect. At Golden Paper, we analyze the main factors that influence bulkness from the factory’s perspective — focusing on raw materials, papermaking processes, and post-treatment techniques.

Why Bulkness of Paper Is Important

Before exploring what affects paper bulkness, let’s understand why it matters.

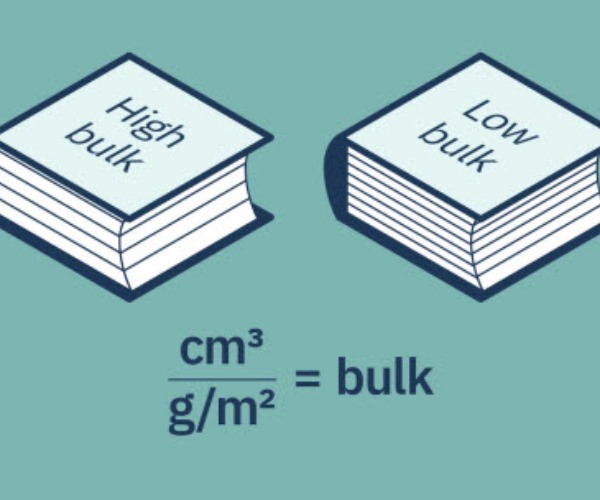

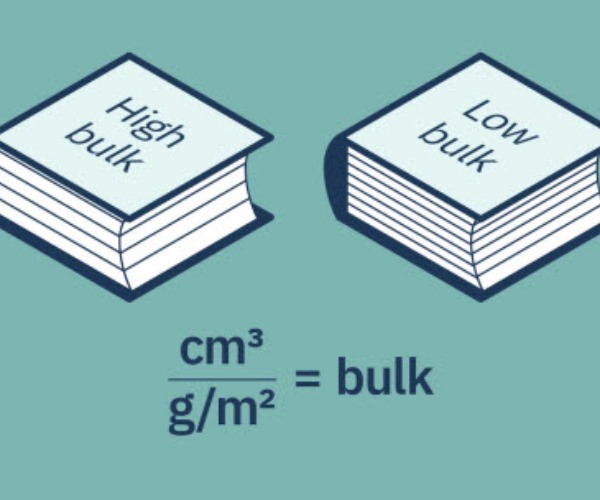

Bulkness refers to the ratio between paper thickness and its basis weight, reflecting how dense or porous the paper structure is. It serves as a balance between cost efficiency and performance.

First, paper with higher bulkness can achieve the same thickness with less fiber, which helps reduce raw material usage and energy consumption. This is beneficial both for paper manufacturers like us and for customers in the printing and packaging industries, as it lowers production costs while improving resource efficiency.

Second, greater bulkness improves the stiffness of paper and paperboard, giving the product better support and a premium feel. For example, in book printing, publishers may use high-bulk paper for book covers to maintain thickness with fewer pages, creating a richer and more high-end appearance.

Additionally, paper with higher bulkness has better opacity and printability, reducing ink show-through and ensuring sharper, fuller print results.

In short, bulkness directly influences not only the cost of production but also the performance and market competitiveness of the final product.

What Can Affect the Bulkness of Paper

Bulkness, defined as the volume per unit weight (usually expressed in cm³/g), depends largely on the fiber arrangement and internal porosity of the paper sheet.

Several factors play a role, including papermaking fibers, pulp type, beating degree, filler usage, pressing and drying processes, and calendering. Let’s look at each of these factors in detail.

Papermaking Fiber Materials

The structure of the fibers used in papermaking is one of the most fundamental factors affecting paper bulkness. Fiber length, thickness, and cell-wall structure all influence the formation of pores in the paper.

Generally, coarse fibers tend to create more voids and a looser paper structure, resulting in higher bulkness. Finer fibers, on the other hand, pack more tightly, making the paper denser and less bulky.

However, bulkness is not just determined by fiber size — it’s also affected by how fibers deform during pressing and drying. Excessive compression can collapse the fiber walls and destroy the pore structure, reducing bulkness.

At Golden Paper, we use high-quality wood pulp and carefully control fiber treatment to preserve elasticity and maintain the desired paper bulk.

Types of Pulp

Different types of pulp have distinct fiber structures and chemical compositions, which significantly affect paper bulk. In general, the ranking of pulp bulkness is as follows:

High-yield pulp (chemical-mechanical pulp) > Thermomechanical pulp > Kraft pulp > Recycled pulp.

High-yield pulp retains more lignin and hemicellulose, keeping the fibers stiffer and less collapsed, which increases porosity and bulk.

Kraft pulp, on the other hand, is chemically treated to remove lignin, making the fibers softer and more flexible, thus creating a denser and less bulky sheet.

The source of the pulp also matters:

Hardwood mechanical pulp > Softwood mechanical pulp, and hardwood kraft pulp > softwood kraft pulp > straw pulp.

Hardwood fibers are shorter and flatter, which helps create a more open and bulky structure.

Beating Process

Beating (or refining) is a key step in the papermaking process that adjusts fiber flexibility and bonding strength. Beating increases fiber bonding and paper strength, but excessive beating makes the paper too compact, reducing bulkness.

When fibers are over-refined, their surfaces become overly fibrillated, which leads to dense sheet formation. Conversely, moderate beating maintains fiber curl and resilience, which can help increase bulk.

Low-consistency beating tends to produce tightly bonded fibers and thus lower bulkness, while high-consistency beating preserves some curl, improving the fluffiness and thickness of the paper.

Fillers

Fillers such as calcium carbonate and kaolin clay are commonly used to improve brightness, smoothness, and printing performance, but they can reduce bulkiness.

Since fillers are denser than fibers, increasing filler content makes the paper more compact and less bulky. Therefore, it’s important to balance filler usage based on the target paper type.

For papers that require higher bulk — such as book paper or lightweight coated paper — the filler content should be carefully controlled or the filler type adjusted to maintain the desired porosity.

Pressing

The pressing stage removes water from the wet paper web, but it also affects paper density. Excessive press pressure compresses the sheet, reducing air gaps and lowering bulkness.

To balance dewatering and bulk, the press pressure should be optimized.

Modern techniques such as the Extended Nip Press (ENP) allow longer contact time under moderate pressure, improving water removal without crushing the fiber structure. This helps maintain both paper strength and bulkness.

Drying

Drying also plays an important role in determining paper bulk. As the drying temperature and time increase, water evaporates and hydrogen bonds between fibers strengthen, making the structure denser and decreasing bulk.

Bulkness is inversely related to the maximum drying shrinkage rate — excessive shrinkage pulls fibers closer together and reduces porosity.

To retain more internal voids, papermakers can lower drying intensity or shorten drying time, preserving a fluffier structure.

Calendering

Calendering is part of the finishing process that enhances surface smoothness and gloss. It can be performed as hard calendering or soft calendering.

In hard calendering, the paper passes through metal rolls under high pressure, compressing the sheet and reducing bulkness.

Soft calendering, however, uses a resilient roll under lower pressure to smooth the surface while keeping more of the internal bulk intact.

Therefore, when bulkness does not meet product requirements, adjustments such as reducing calendering pressure, decreasing the number of nips, or using soft calenders can help improve thickness and tactile quality.

Conclusion

In summary, the bulkness of paper is affected by multiple factors — from fiber type and pulp properties to pressing, drying, and calendering processes. At Golden Paper, we carefully balance physical performance and cost efficiency through advanced formulations and optimized production techniques. Contact us today to request samples or a custom quote for your next paper project!

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id