Introduction

In the printing and packaging industry, labels are more than just carriers of product information. They are also a vital part of a brand’s identity. If you are looking for a labeling solution that works efficiently, adapts to a variety of surfaces, and saves production time, self-adhesive stickers are an option you cannot overlook. They require no additional glue or heat and can be applied simply by peeling and sticking, which makes them ideal for both high-speed automated labeling and manual application. This article will provide you with useful knowledge about self-adhesive sticker, which we hope will help you when searching for a reliable sticker supplier.

What Does Self-Adhesive Sticker Mean?

A self-adhesive sticker is a type of label material that comes with its own adhesive layer, allowing it to be applied directly to a surface without the need for extra glue. Its greatest advantage is convenience because the user only needs to peel away the backing liner and apply the label to the desired location for it to adhere firmly. In some cases, the label can be easily removed and replaced. Depending on the purpose, self-adhesive labels can be permanent or removable. Depending on the surface finish, they can be glossy, matte, transparent, or metallic. Depending on the application environment, they can be designed to withstand high or low temperatures, resist water or oil, or endure chemical exposure.

The Components of a Self-Adhesive Sticker

Although a label may appear to be a single piece, it is actually made of three layers that are carefully combined, with each layer having its own specific function and technical requirements.

Facestock

The facestock is the top layer of the label, which directly displays printed content and visual effects. The choice of facestock determines the appearance of the label, the quality of printing, and the environments in which it can be used. To achieve the best results, it is important to select the right facestock according to the intended conditions. The most common paper facestocks include high gloss art paper, semi-gloss art paper, woodfree paper, and thermal paper. These paper materials have high brightness, which ensures that text and images appear clear and sharp. Coated art paper has a glossy finish and is often considered a premium option for high-end labels. Woodfree paper is suitable for producing plain labels that can be written on for notes or temporary records. Thermal paper does not require a ribbon and can be printed quickly using a thermal printer, making it ideal for large-scale printing needs such as supermarket price tags and logistics waybills.

There are also synthetic facestocks such as polypropylene (PP), polyester (PET), and polyvinyl chloride (PVC). These materials are waterproof, oil-resistant, wear-resistant, and tear-resistant, which makes them suitable for durable self-adhesive stickers used on items such as food and beverage packaging, personal care products, electronics, and electrical appliances.

Special facestocks, such as metallized paper in gold or silver, transparent films, thermal transfer films, tamper-evident paper, and anti-counterfeiting materials, can provide unique functions. They are often used to enhance brand image, create traceable security labels, or produce premium packaging that gives products a high-end appearance.

The selection of facestock should take into account the printing method, such as offset printing, flexographic printing, screen printing, or thermal transfer printing. It should also consider the environmental conditions, such as temperature, humidity, and light exposure, as well as the budget.

Adhesive

The adhesive is the key component that allows the sticker to stick to a surface. Different adhesive formulas directly affect the bonding strength, temperature resistance, moisture resistance, and removability of the label. Permanent adhesive has strong bonding power and is difficult to remove once applied. It is suitable for long-term labeling needs where important information must remain intact, such as shipping labels and asset labels. Removable adhesive has moderate bonding strength, which allows the label to be peeled away without leaving residue. This makes it ideal for price tags or temporary labels, especially when product information may change over time.

Special adhesives are developed to meet specific requirements, such as high-temperature adhesive, low-temperature adhesive, freezer-grade adhesive that maintains stickiness at -20°C or lower, waterproof and oil-resistant adhesive, and repositionable adhesive that allows the label to be applied and removed multiple times.

The quality of the adhesive directly impacts the user experience. If the adhesive layer is too thick or too strong, it may leave residue when removed. If the adhesive is too weak, the label may curl or fall off. High-quality self-adhesive labels are tested in various environments to ensure stable performance under different conditions.

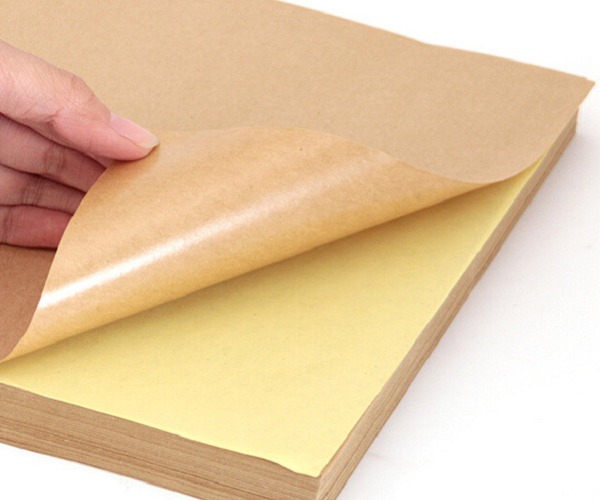

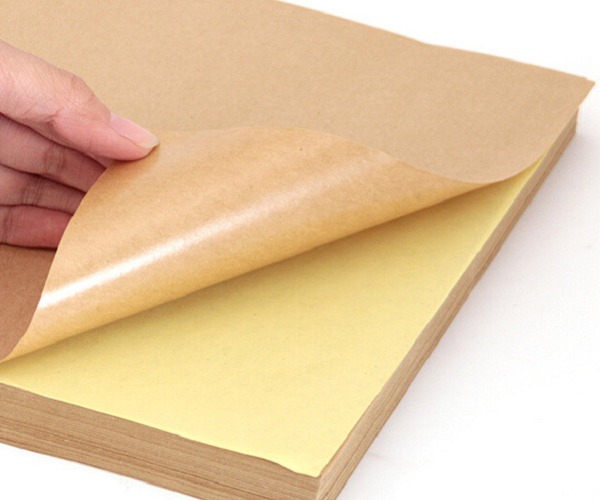

Liner

The liner is the backing layer of the label that protects the adhesive before use and ensures the label can be smoothly applied to the intended surface when peeled away. It is usually made of paper or film coated with a release agent such as silicone to allow easy removal of the label. Glassine liner has a smooth surface, high density, and good strength, making it the most common choice for high-speed automatic labeling machines. White or yellow kraft liner is thicker and more rigid, making it suitable for manual labeling and special printing requirements.

Although the liner is discarded after the label is applied, it plays an important role in the production, storage, and application process. A high-quality liner helps prevent curling, tearing, or misalignment of labels during use, which improves labeling efficiency.

Conclusion

Self-adhesive stickers combine convenience, versatility, and customization, making them widely used across industries such as food and beverages, personal care, electronics, and logistics. With over 20 years of paper manufacturing experience, we Golden Paper can provide a variety of self-adhesive label materials and custom label printing solutions. Whether you require permanent adhesive labels, removable adhesive stickers, or specialized custom designs, we can create a labeling solution that meets your specific needs and enhances the value of your products.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id