Introduction

In the commercial paper towel market, TAD (Through Air-Dried) tissue are becoming the preferred choice for high-end locations because their drying process is completely different from traditional paper products. If you’re responsible for purchasing or managing hygiene supplies, understanding how TAD technology works—and why it performs better—will help you make a more efficient, cost-effective, and sustainable buying decision.

What Is TAD Paper?

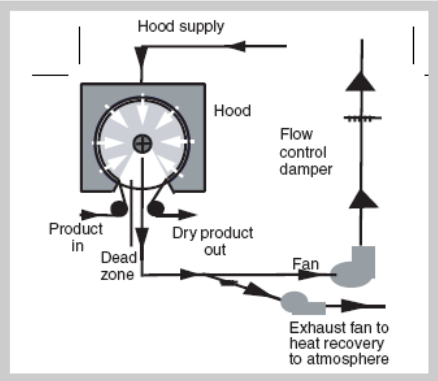

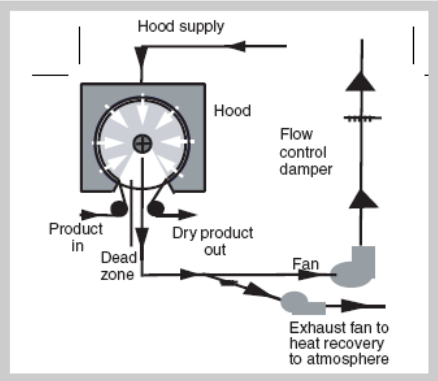

TAD tissue are produced using an air-drying process where heated air passes through the paper web to remove moisture, instead of relying on heavy pressing. Because the fibers are not compressed, they keep their natural structure, creating a more open and three-dimensional network. This allows the paper to absorb water faster and maintain strength even after becoming wet.

During manufacturing, the TAD process preserves more air pockets within the sheet, giving the paper higher absorbency and a softer feel. These advantages make TAD paper a standard choice for premium towel products in North America and Europe, especially in commercial restrooms where performance matters.

TAD Paper vs. Traditional Paper Towels

The differences between TAD tissue and traditional paper towels go far beyond softness. Their performance affects usage, customer satisfaction, and long-term operating costs.

Absorbency

Because TAD tissue have an open fiber structure, they absorb water much faster and hold significantly more moisture than regular paper towels. This means users need fewer sheets to dry their hands, which dramatically reduces consumption in high-traffic restrooms.

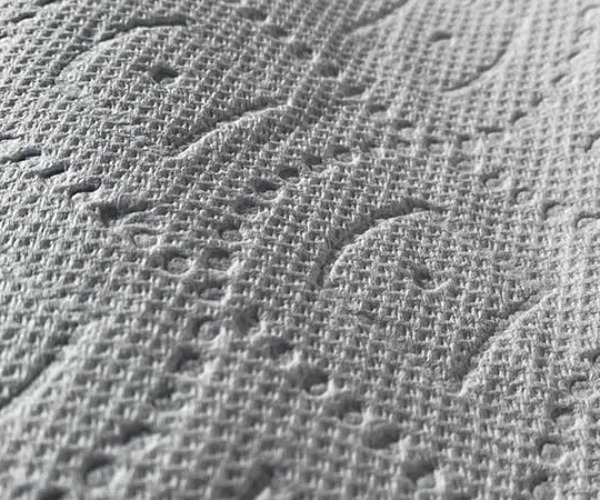

Softness

Since TAD technology avoids heavy compression, the fibers maintain their natural elasticity. This results in a noticeably softer feel, making TAD tissue more suitable for hotels, airports, and other environments where comfort and experience are important.

Strength

Even though TAD tissue feel softer, they maintain strong wet strength. They do not easily tear when saturated, allowing users to dry their hands more efficiently without pulling additional sheets.

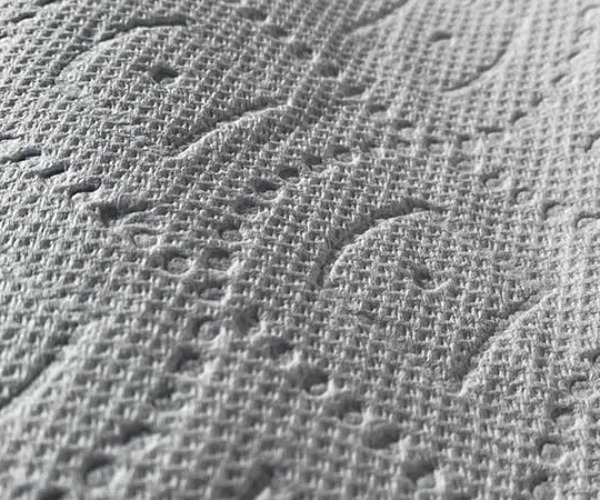

Thickness & Bulk

TAD tissue are thicker and more voluminous due to their open, structured design. This creates a more premium tactile experience and makes the product feel higher-quality compared with traditional options.

Usage Efficiency

Because TAD tissue absorb more and stay strong when wet, guests typically use fewer sheets each time. This efficiency reduces long-term consumable costs and helps businesses lower maintenance and restocking frequency.

Environmental & Cost Benefits

Some buyers initially assume that TAD tissue are more expensive. However, once real-world usage is considered, TAD products often reduce overall spending in high-use environments.

TAD tissue deliver better absorbency, so the amount used per person naturally decreases. Lower usage means fewer refills, less storage pressure, and less labor required for maintenance.

Golden Paper also offers TAD tissue made with FSC-certified fiber, PEFC fiber, or recycled fiber, helping companies meet sustainability standards. For businesses working on ESG goals, environmental audits, or supply-chain compliance, TAD products offer an advantage by meeting recognized global certifications.

With reduced waste, improved efficiency, and stronger sustainability alignment, TAD tissue offer long-term economic and environmental value.

Where TAD tissue Perform Best

The performance benefits of TAD tissue make them ideal for spaces that demand comfort, efficiency, and hygiene.

Airports and luxury hotels value softness, quick absorbency, and an elevated guest experience. Large office buildings and corporate campuses focus on overall consumption and long-term costs, making TAD efficiency particularly beneficial.

Medical facilities require fast absorbency and strong wet-strength performance to minimize repeated touching and the risk of contamination. Restaurants and foodservice operations benefit from TAD’s ability to handle both water and grease more effectively. High-end retail stores and shopping centers also prefer towels with a thicker, softer texture to upgrade their customer experience.

TAD technology is equally effective in kitchen towel applications. Thanks to stronger absorbency and oil-pickup capability, TAD kitchen rolls are widely used in commercial kitchens, food preparation facilities, and premium household markets.

Advantages of Golden Paper’s TAD Tissue

At Golden Paper, we have extensive experience producing TAD products and have built competitive advantages through advanced equipment and process management.

We offer both virgin wood pulp and bamboo pulp TAD tissue. Our bamboo-pulp TAD paper is unique in the industry—bamboo fiber has naturally higher strength and grows faster, making it an excellent choice for sustainability-focused markets.

Unlike traditional embossed paper towels, our embossing is completed during the pulp-forming stage rather than after the sheet is finished. Pulp-stage embossing provides stronger pattern stability, reduces dusting and edge breakage, and improves overall absorbency. This process creates a more durable and consistent product suitable for demanding commercial environments.

Our production line features a 2850 mm machine width, allowing us to supply both jumbo rolls and finished products to meet the needs of converters, OEM buyers, and large distributors. Golden Paper also holds FDA, FSC, and PEFC certifications, ensuring our products meet regulatory and sustainability requirements in North America, Europe, the Middle East, and other strict markets.

With these process and certification strengths, Golden Paper continues to deliver TAD products with superior absorbency, wet strength, and softness—supporting premium facilities in maintaining high-quality hygiene standards.

Conclusion

Now that you understand how TAD technology works and why TAD tissue perform so well, your final purchasing decision will depend on your specific hygiene and operational needs. If you want more information about TAD products or wish to request pricing and samples from Golden Paper, feel free to contact us anytime.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id