Introduction

With the rapid growth of take-out food, coffee shops, and fast-service restaurants, paper cups have become one of the most widely used food-contact packaging products. Whether a cup is used for hot drinks, cold drinks, or general single-use service, its safety and performance depend entirely on whether the raw materials meet food-grade standards. Understanding what a paper cup is made of helps you make better purchasing decisions and avoid potential safety risks.

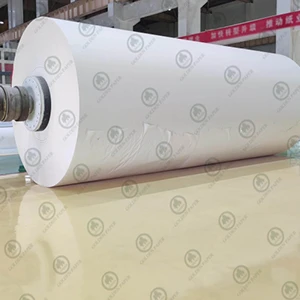

Common Raw Materials for Paper Cups

Base Material: Requirements for Food-Grade Paperboard

Food-grade paperboard is the main body of a paper cup. It provides structure, supports the cup shape, and determines whether the cup is safe and strong enough during use. In China, compliant cupstock must meet the GB 4806.8 Food Contact Paper and Paperboard standard.

Paperboard Must Be Uniform and Dense

High-quality cupstock paper requires uniform fiber distribution, a smooth surface, and good density. Stable fiber structure improves stiffness and prevents deformation or leakage when holding drinks. Most food-grade cupstock is made from virgin wood pulp or premium bleached pulp through refined pulping and calendering to ensure uniformity.

No Impurities, Odors, or Contaminants

Food-contact paper must be free from harmful substances that could migrate into beverages—such as heavy metals, fluorescent whitening agents, ink residues, or small particles. Since paper cups directly contact drinks, any contamination in the paperboard can pose safety risks when exposed to hot water or acidic beverages.

High Stiffness and Strength Are Essential

Stiffness and ring-crush strength determine how strong and durable a cup will be. If the paperboard is too soft, the cup may collapse—especially when hot drinks cause steam absorption and fiber softening. Strong, stiff paperboard is the foundation for a safe user experience.

Recycled Wastepaper Must Not Be Used Directly

Food-grade paper cups cannot be made from un-deinked or non-purified recycled paper. Wastepaper often contains ink, adhesives, plasticizers, and other chemicals that may migrate into beverages. For safety and compliance, certified food-grade cupstock must rely mainly on controlled virgin fiber sources.

Functional Coating: Food-Grade PE Film for Leak Resistance

A plain sheet of paper cannot hold water. Without a coating, the paper would break after long contact with liquids. This is why food-grade PE (polyethylene) coating is essential for paper cups. It adds water resistance, oil resistance, and prevents beverages from seeping into the paper fibers.

Food-Grade PE Coating Ensures Safety

The PE coating on the inner wall of a paper cup must meet food-contact safety requirements and must not contain fluorescent agents, heavy metals, or solvent residues.

Coating Must Be Even, Without Gaps or Defects

PE coating is typically applied using an extrusion coating process to bond the film evenly onto the paper surface. A qualified PE coating should have:

Uniform coverage

No thin spots or over-thick areas

No pinholes, bubbles, scratches, or wrinkles

The more uniform the coating, the better the leak-resistance and durability in actual use.

Strong Adhesion Ensures Smooth Cup Forming

Paper cup forming involves curling, sealing, and heat-bonding. If the coating does not adhere well, the heat-seal may fail and the seams may crack, causing leakage. This is why PE-coated cupstock must offer both safety and good processability.

Special Requirements: Hot Drink Cups vs. Cold Drink Cups

Paper cups look similar, but the materials differ significantly depending on whether they are used for hot or cold drinks. When purchasing cupstock, you need to match the raw material with the actual end-use scenario to avoid common problems—such as using single-PE cold-cup paper for hot beverages.

Hot Drink Paper Cups: Heat-Resistance and Stability

Hot drink cups are used for coffee, tea, and hot water, so the material requirements are stricter.

PE Coating Must Withstand 100°C+

High temperatures can soften or release substances from the PE film. Hot-cup PE coating must:

Resist melting or delamination

Avoid releasing odors or harmful substances

Maintain tight sealing even under high heat

Higher Stiffness to Prevent Cup Collapse

Steam from hot drinks can soften fibers. If the base paper lacks stiffness, the cup may deform or become uncomfortable to hold. Strong, stiff cupstock is necessary for hot cups.

Optional Double-Wall Structure for Better Insulation

Some hot drink cups use a double-wall or sleeve design to add an air layer for insulation, improving comfort and preventing heat transfer.

Cold Drink Paper Cups: Low-Temperature Resistance & Moisture Control

Cold drink cups are used for iced coffee, soda, iced tea, and other chilled beverages. Their priorities are different.

PE Coating Must Resist Low-Temperature Brittleness

Some PE films become brittle in low temperatures, affecting leak resistance. Cold-cup coatings must stay smooth, flexible, and resistant to condensation.

Cupstock Must Resist Softening from Moisture

Cold drinks cause condensation on the cup’s surface. If the paper absorbs moisture easily, it may soften. High-density paperboard and uniform PE coating reduce moisture absorption and keep the cup firm.

Some Cold Cups Need Additional Outer-Wall Moisture Protection

For drinks with heavy condensation, some cups use anti-moisture treatment on the outside to prevent slipping and improve user experience.

Conclusion

Choosing the right raw materials directly affects the safety, performance, and compliance of paper cups. From food-grade paperboard to PE coating and different structures for hot and cold drinks, every detail matters. As a professional supplier of food-grade cupstock and PE-coated paper, we Golden Paper offer materials that meet international standards and support customization. If you’re looking for reliable paper cup raw materials, feel free to contact us for samples and pricing.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id