Introduction

As the paper replacing plastic trend continues to advance, food packaging materials are evolving toward higher safety, stronger sustainability, and greater specialization. Among them, food grade PE coated paper has become widely used in disposable food containers due to its balance of stiffness, liquid resistance, and food safety performance. From an industry perspective, common food grade PE coated paper can generally be divided into three main types: cupstock PE coated paper, kraft PE coated paper, and white paperboard PE coated paper. Next, this article will introduce these three types from the aspects of base paper structure, mechanical properties, and application scenarios. If you are interested, please continue reading.

Food Grade PE Coated Paper Types

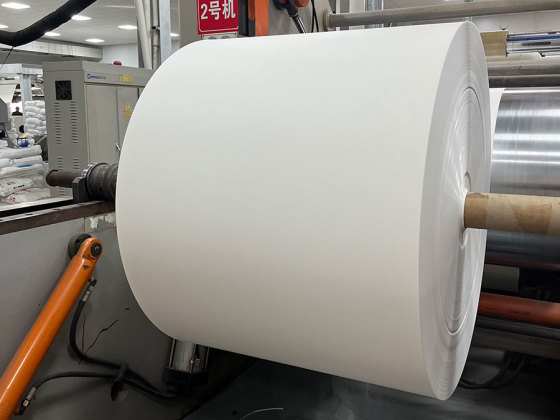

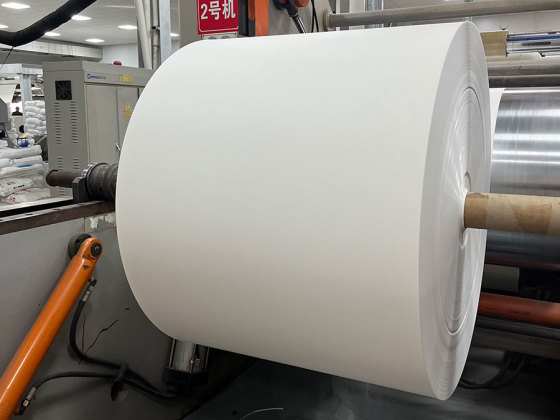

Cupstock PE Coated Paper

Cupstock PE coated paper, also known as coated cup paper, refers to paper that is laminated with a polyethylene (PE) barrier layer on the surface of the base paper through an extrusion coating process. This PE coating effectively prevents liquid penetration and is the key structural element that allows paper cups to hold beverages.

In terms of paper characteristics, cupstock paper is usually designed with a relatively low basis weight to meet the flexibility and folding requirements of cup forming. Although the base paper grammage is not high, the PE coating significantly improves water resistance and anti-leakage performance. This makes it suitable for both hot and cold beverage applications.

In practical use, cupstock PE coated paper is widely applied in: various beverage cups, cold drink cups, milk tea cups, coffee cups, snowflake cups, advertising cups, promotional paper cups, paper bowls, and some lightweight fast-food packaging.

Since cupstock paper often comes into direct contact with liquid food, food grade cupstock PE coated paper requires strict control over raw material selection and production processes.

When sourcing this paper, you should ensure that the base paper is odor-free, contains no harmful additives, and that the PE coating is stable and does not delaminate.

Only under these conditions can end-user food safety be effectively guaranteed.

PE Coated Kraft Paper

Kraft PE coated paper uses kraft board as its base paper and is a typical food packaging material that emphasizes strength and durability. In the industry, “kraft board” generally refers to a category of paper positioned between kraft paper and paperboard.

Its most notable features are an intact fiber structure and high physical strength. From a classification perspective, paper below 120 gsm is usually considered kraft paper, while paper above 120 gsm is typically referred to as kraft board.

Kraft board places high requirements on both raw materials and manufacturing processes.

Key performance indicators include burst strength, ring crush strength, tear resistance, and water resistance.

At the same time, basis weight, thickness, density, burst index, tensile strength, sizing degree, and moisture control are all critical parameters used to evaluate kraft board quality. During procurement, strict control of these parameters is necessary to ensure smooth production and consistent finished product quality.

After food grade PE coating, the application range of kraft board is further expanded. It is commonly used in high-strength cup bodies for milk tea and coffee cups, popcorn buckets, food paper tubs, takeaway food packaging, and oil- and water-resistant packaging containers.

These applications require not only sufficient stiffness and support, but also tear resistance to protect food and beverages.

Such packaging helps prevent leakage, contamination, and potential burns to users. The core value of kraft PE coated paper lies in providing enhanced structural support while maintaining food safety compliance. It is particularly suitable for food packaging scenarios with high demands for load-bearing capacity, stiffness, and durability.

White Paperboard PE Coated Paper

White paperboard is a high-quality paper with higher basis weight and a rigid structure. It is typically made from natural plant fibers such as wood pulp or bamboo pulp and processed through calendering or embossing.

Its main advantages include high whiteness, good smoothness, and an excellent visual appearance.

With the growing emphasis on brand packaging, demand for white paperboard in food packaging has increased year by year. However, it is important to emphasize that food grade white paperboard is fundamentally different from ordinary white paperboard in terms of application requirements.

Although their basic production processes are similar, food grade white paperboard is subject to much stricter controls in the following areas. Fluorescent whitening agents are not allowed. Harmful chemical components must not be present. Raw materials and production processes must comply with relevant food contact material regulations.

Food grade white paperboard PE coated paper is commonly used in packaging structures that directly or indirectly contact food. While providing effective resistance to liquid and grease, it also delivers excellent printability and brand presentation. Typical applications include high-end milk tea cups and coffee cups, blind box paper cups and customized brand cups, and food packaging with high requirements for appearance and safety.

In essence, food grade white paperboard PE coated paper is not just a packaging material. It is also a critical component of the overall food safety system.

Whether it is cupstock PE coated paper, kraft PE coated paper, or white paperboard PE coated paper, all share the same fundamental requirement of food grade safety. However, their performance priorities differ depending on the application. Lightweight design, liquid resistance, structural strength, and visual performance together form the core evaluation system for food packaging paper.

Conclusion

In actual sourcing and application, only by selecting the appropriate PE coated paper based on product type, usage scenario, and compliance requirements can you ensure food safety while achieving a reasonable balance between packaging performance and cost. This is the fundamental reason why food grade PE coated paper continues to be widely adopted in modern food packaging systems. As a paper manufacturer with over 20 years of professional experience, Golden Paper can supply a wide range of paper products. Welcome to contact us for pricing and samples.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id