Introduction

In the packaging and printing industry, duplex board with white Back and folding box board (white card paper) are often compared. At first glance, they may look similar, but they differ significantly in materials, manufacturing process, physical performance, print compatibility, and post-processing. Understanding these differences helps you make more informed choices in design, printing, and procurement, balancing cost, appearance, and functionality.

Differences Between Duplex Board and Folding Box Board

Appearance

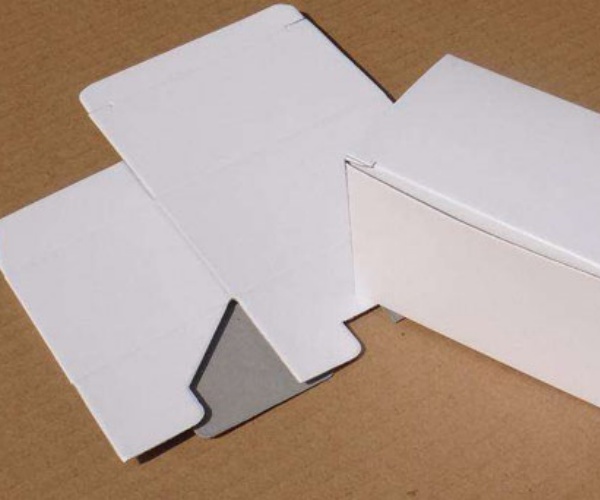

Duplex board typically has one white side and one grey side. The white surface is coated with fillers and calendered, making it suitable for single-sided color printing, while the grey backing—usually made from recycled or mechanical pulp—is rougher and less refined.

Folding box board is white on both sides, smooth, and made from 100% bleached chemical pulp, often with additional coating or calendering. Its higher whiteness, smoothness, and cleanliness make it ideal for double-sided printing and premium applications like business cards, invitations, or luxury packaging, where consistent and high-quality print results are crucial. Duplex board is more cost-effective and widely used for single-sided printing or hidden interior structures.

Materials and Manufacturing Process

Duplex board usually employs layered construction:

The top layer uses higher-whiteness pulp for better print quality.

The core and backing often include recycled fibers or mechanical pulp to increase thickness and stiffness.

Production uses multi-ply cylinder or long webboard machines to balance strength and cost.

Folding box board emphasizes pure raw materials and precise layering:

Top and bottom layers use chemical pulp from softwood, with the core optionally using chemical-mechanical pulp.

Fillers like calcium carbonate and barium sulfate are added, and neutral sizing agents (AKD) are applied.

Final surface finishing through calendering or coating ensures smoothness and printability.

Performance

Duplex board usually ranges from 200–500 g/m² with higher moisture content (~10%), making it more sensitive to humidity changes. Pre-print conditioning and oven temperature control are important to prevent warping, cracking, or color deviation.

Folding box board typically ranges 200–400 g/m², but even at the same weight, its denser fiber structure and higher stiffness provide superior burst strength, fold resistance, and dimensional stability. White card papers are graded for whiteness, smoothness, and dust content (e.g., A/B/C), ensuring excellent performance in high-precision printing, UV coating, hot stamping, and embossing.

Printing Effects

Duplex board is best suited for single-sided, moderate coverage printing. Heavy double-sided ink, high-energy UV curing, or high drying temperatures may cause warping, cracking, or backing powdering.

Folding box board can withstand complex post-processing: lamination, thermoforming, embossing, hot stamping, spot UV, and heavy ink coverage. Different grades and weights may vary in foldability and stiffness, so always confirm minimum bending radius and die-cut folding performance with your paper supplier.

Cost Considerations

Duplex board is more cost-effective, with flexible specifications (sheets: 787×1092mm, 889×1194mm; rolls: custom widths), suitable for single-sided packaging where cost is a concern.

Folding box board has higher raw material costs and stable physical properties, positioning it for premium markets (sheet sizes: 787×1032mm, 880×1230mm) compatible with standard printing equipment.

Modern procurement also considers sustainability, traceability, and compliance. Folding box board more easily provides bleached pulp certification or FSC approval, while duplex board emphasizes recycled fiber use for environmental benefits. For food or cosmetic packaging, always check whether sizing agents and coatings meet food contact safety standards.

Conclusion

After reading this, you should have a clear understanding of the differences between duplex board and folding box board, helping you make better paper procurement decisions for packaging and printing. With over 20 years of experience, Golden Paper offers professional advice and a wide selection of papers, including duplex board, folding box board, and other varieties. Contact us for quotes and samples to ensure the best results for your projects.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id