Introduction

In the food and beverage industry, packaging is more than just a protective layer—it represents your brand and your commitment to sustainability. Liquid packaging board has become the go-to material for many companies. Why choose it? Because it can safely hold liquids while reflecting your promise of quality and environmental responsibility. Keep reading to find out why it’s the preferred choice for modern beverage packaging.

The Characteristics of Liquid Packaging Board

Technical Performance: The Logic Behind Its Structure

Why can liquid packaging board replace plastic and glass as the preferred liquid packaging material? Its key strengths are high stiffness, excellent barrier properties, and printing adaptability. Let’s break it down.

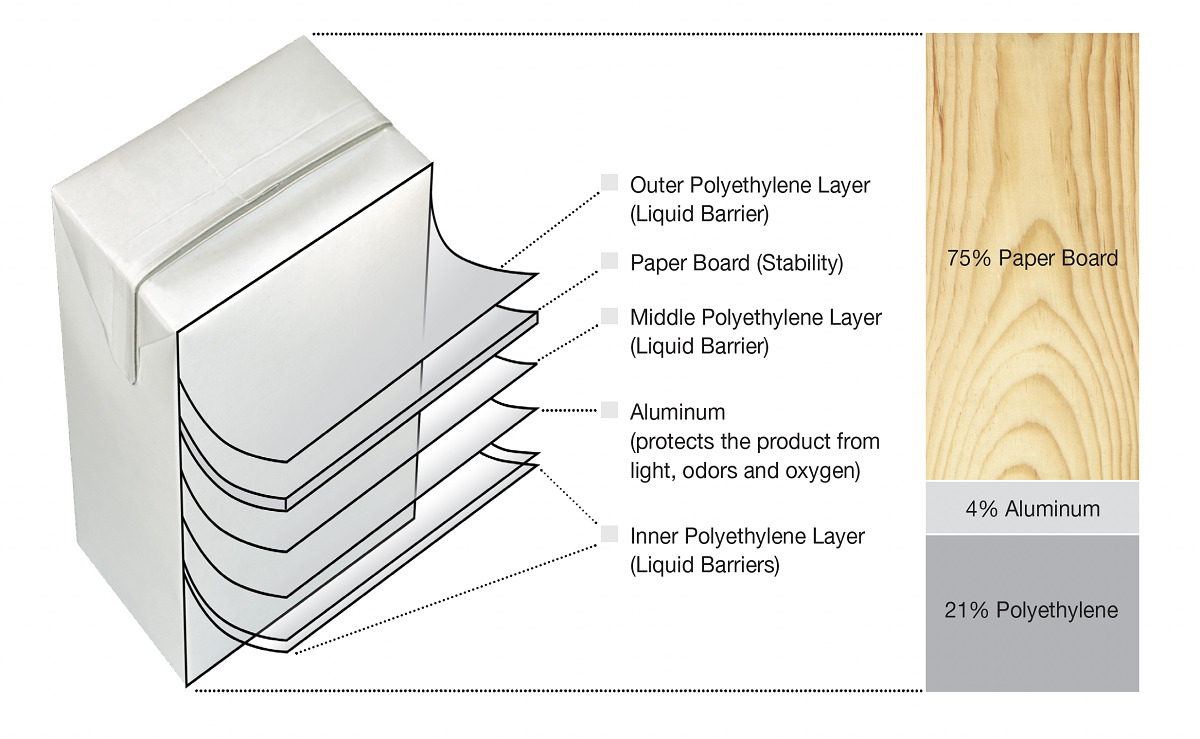

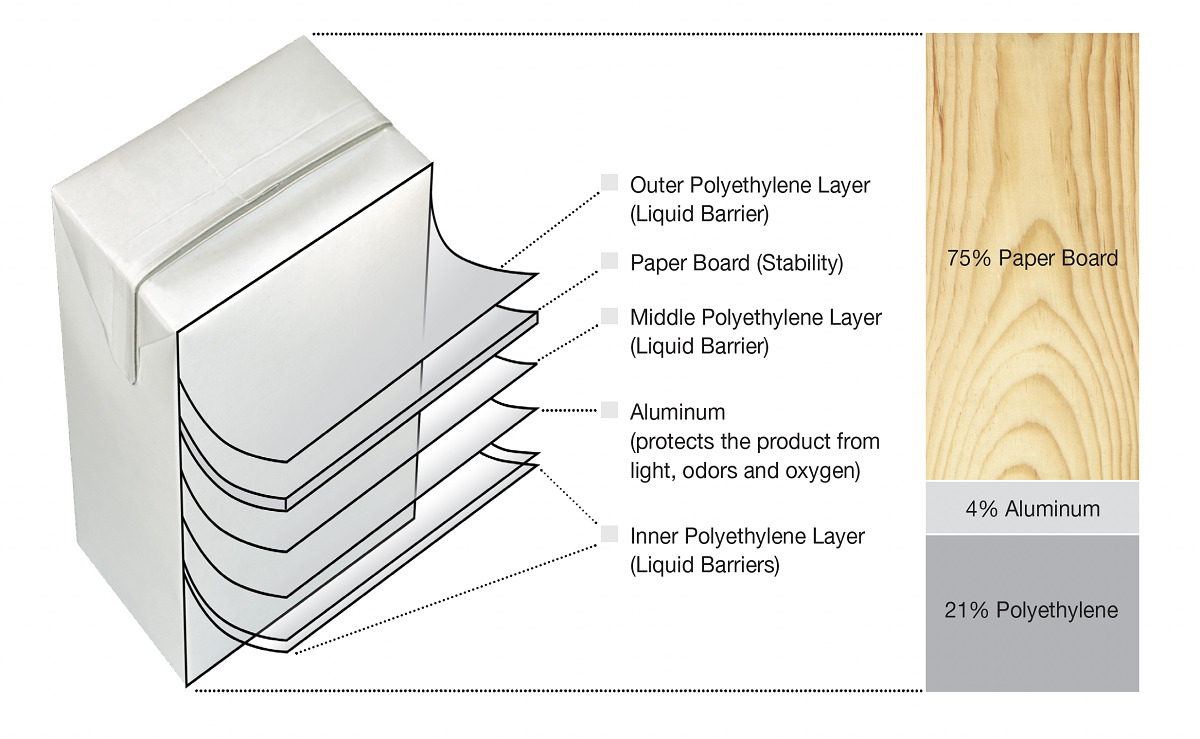

The Structure of Liquid Packaging Board

Liquid packaging board usually has a three-layer structure: top layer, core, and bottom layer. The core uses unbleached long-fiber pulp with fibers over 1.2mm long. This gives the board stronger bonding and tensile strength. The fibers are arranged in a cross-linked network, creating a stable skeleton that provides stiffness. The top and bottom layers use bleached chemical pulp mixed with short fibers to ensure smooth surfaces and good printability. This multilayer structure makes liquid packaging board ideal for aseptic packaging and carton manufacturing in dairy, juice, and plant-based drink industries.

The Pulp of Liquid Packaging Board

We use 100% wood pulp, refining it to over 35°SR to increase surface roughness and fiber bonding. During pressing, a multi-stage system applies pressures from 85kN/m to 720kN/m, ensuring thorough water removal, dense structure, and enhanced stiffness and deformation resistance. High-quality virgin wood pulp not only improves paper stiffness but also ensures consistent forming strength and reliable performance during liquid filling and sealing.

The Coating of Liquid Packaging Board

At Golden Paper, we apply a three-layer coating process using functional fillers like calcium carbonate, kaolin, and SA latex. The pre-coat fills gaps between fibers, the top coat improves surface density and printability, and the back coat boosts water resistance and structural stability. Coating weight is carefully controlled at 12–18 g/m² to balance performance without adding unnecessary weight. Our advanced coating technology provides excellent ink absorption and surface smoothness, making the board compatible with both offset and flexographic printing.

The Processing of Liquid Packaging Board

During drying, we use segmented drying curves to prevent uneven internal stress. In calendering, soft calenders apply 10–40 kN/m pressure to enhance smoothness and gloss without damaging fibers, creating a perfect base for printing and lamination. The precise calendering process also ensures dimensional stability, helping maintain print registration accuracy and high lamination adhesion in beverage packaging lines.

The Environmental Attributes of Liquid Packaging Board

The eco-value of liquid packaging board is not just in the paper—it lies in recyclability, biodegradability, and low carbon footprint. As sustainability becomes central to packaging innovation, more brands are switching to paper-based materials like liquid packaging board to reduce plastic dependence.

Recyclability

Liquid packaging board fits into existing paper recycling systems, achieving much higher recovery rates than plastic bottles or aluminum-laminated materials. In Europe, recycling rates already exceed 70%, making it a key material for the circular economy.

Biodegradability

Traditional PE-coated boards are not easily degradable. New water-based coated liquid packaging boards avoid PE, aluminum, or PFAS materials, can naturally decompose, reduce microplastic pollution, and comply with EU packaging regulations and China’s carbon neutrality goals.

Low Carbon Footprint

Made from renewable forestry certified by FSC or PEFC, liquid packaging board production consumes less energy and emits far less CO₂ than plastic or aluminum. LCA data shows carbon emissions can be reduced by over 30%.

Environmental benefits are more than material advantages—they also help brands achieve ESG goals and regulatory compliance.

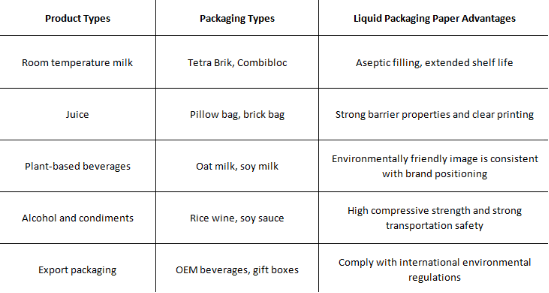

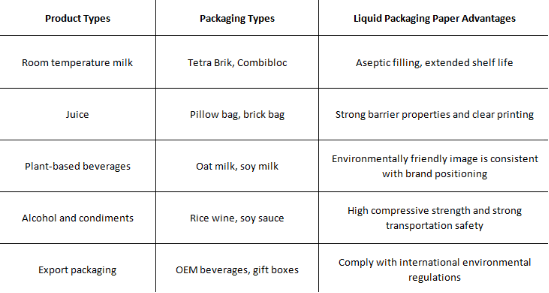

The Market Trends of Liquid Packaging Board

Applications of liquid packaging board have expanded beyond traditional dairy to plant-based drinks, functional beverages, and other emerging products. Consumers increasingly value health, sustainability, and convenience, making liquid packaging board a subtle yet powerful asset for new brands. Its eco-friendly image aligns perfectly with brands seeking differentiation.

Why Liquid Packaging Board Is Becoming More Popular

Filling Stage: Our liquid packaging board has high stiffness and heat-seal compatibility, ideal for Tetra Pak, Combibloc, and other high-speed filling machines. It ensures efficient filling and low package breakage.

Transport Stage: Compared to glass, the board is lightweight, strong, and stable for long-distance transport and stacking. Reduced weight also lowers logistics costs.

Retail Stage: Coated with short fibers, the smooth surface ensures high-quality printing, sharp graphics, and clear QR codes, enhancing brand recognition and consumer engagement.

Consumption Stage: Lightweight, easy-to-open, and recyclable, liquid packaging board meets modern consumers’ demand for eco-friendly and convenient packaging.

Liquid packaging board is more than a material—it’s a trust bridge between brands and consumers.

Conclusion

As packaging evolves, liquid packaging board is set to capture a larger share of the liquid packaging market. According to Philip Carder, the market is projected to reach 4.9 million tons by 2028. If you’re looking for high-quality liquid packaging materials, Golden Paper offers a variety of boards and tailored solutions to meet your business needs.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id