Introduction

As global temperatures keep rising, more people rely on air conditioning. However, AC units are not always suitable—especially in livestock houses, greenhouses, and industrial workshops. In these environments, a different cooling solution is needed: cooling pad kraft paper. As the core material of evaporative cooling pads, cooling pad kraft paper plays an irreplaceable role. So, what exactly is cooling pad kraft paper, and why is it so important? In this article, you’ll learn the definition, benefits, and applications of cooling pad kraft paper.

Definition of Cooling Pad Kraft Paper

Cooling pad kraft paper is a specialty paper made from kraft paper base. It is primarily used in manufacturing evaporative cooler pads. Unlike regular kraft paper, cooling pad kraft paper requires not only high mechanical strength but also excellent water absorption and durability.

Its role goes beyond simply providing structural support. In high-temperature, high-humidity, and long-running conditions, cooling pad kraft paper must maintain stability to ensure effective cooling. In short, it’s the invisible “core” that determines whether an evaporative cooling pad can truly deliver cooling, humidifying, and air-purifying effects.

Key Advantages of Cooling Pad Kraft Paper

High Stiffness

One of the most notable features of cooling pad kraft paper is its stiffness. This comes from strong fiber selection and specialized papermaking technology. While standard kraft paper softens and collapses in humid environments, high-stiffness cooling pad kraft paper maintains its honeycomb structure even after long water exposure.

With higher fiber density and grammage, plus physical and chemical reinforcement, the paper resists deformation. This ensures that the cooling pad keeps its ventilation and water channels intact for long-term use.

Excellent Water Absorption

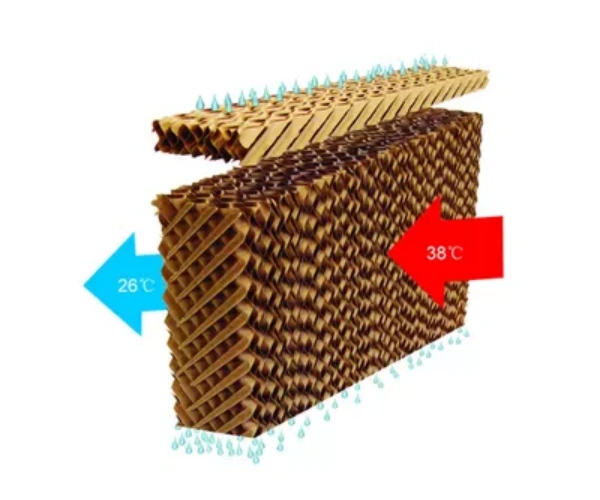

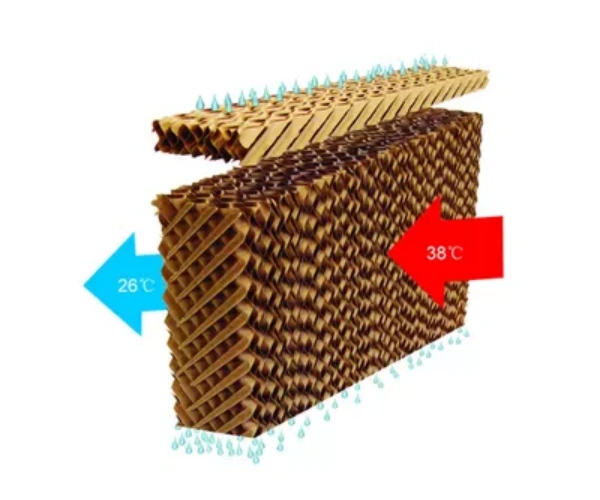

The cooling process relies on water flowing from the top of the pad and forming a thin film across its corrugated surface. As evaporation removes heat, the water absorption capacity of the paper directly impacts cooling efficiency.

Cooling pad kraft paper is engineered for fast absorption and even distribution of water throughout its fibers. This prevents uneven wetting and allows the pad to deliver consistent, efficient cooling.

Long-Term Durability

Evaporative cooling pads are often used continuously for months or even years. Poor-quality paper can delaminate, shed fibers, or rot under constant water circulation and airflow.

At Golden Paper, our cooling pad kraft paper is manufactured with enhanced fiber bonding and improved resistance to hydrolysis. This gives it superior strength and long service life, reducing the frequency of pad replacement and lowering costs for end users.

Eco-Friendliness

Sustainability is increasingly important in the paper and cooling industry. That’s why we recommend producing cooling pad kraft paper from environmentally friendly kraft pulp. This type of paper contains no harmful substances, is recyclable, and meets strict export standards for eco-sensitive markets. Choosing eco-friendly cooling pad kraft paper ensures compliance with global environmental regulations while protecting the planet.

Applications of Cooling Pad Kraft Paper

Cooling pad kraft paper only reveals its true value once it is processed into evaporative pads. These pads are widely used across several industries. If you’re planning to manufacture cooling pads using our raw paper, here are some profitable application markets:

Livestock Farms

In poultry houses, pig farms, and cattle sheds, high temperatures can cause heat stress, leading to reduced feed intake, lower egg production, and higher mortality rates. Evaporative cooling systems can reduce indoor temperatures by 6–10°C while increasing humidity. This relieves heat stress, improves animal health, and boosts overall productivity. For livestock operations, cooling pad kraft paper for animal houses is essential.

Greenhouses

Crops such as vegetables, flowers, and mushrooms are highly sensitive to temperature and humidity. Cooling pads in greenhouses not only reduce temperature but also regulate moisture, creating a stable microclimate. Thanks to their strong water absorption and quick evaporation, cooling pads made with high-quality paper support healthy crop growth and increase yields.

Industrial Workshops

In large factories, warehouses, and entertainment venues, relying solely on air conditioning is both costly and energy-intensive. By combining cooling pads with negative pressure fans and water circulation, companies can achieve efficient cooling and ventilation. These systems also help filter dust and improve indoor air quality, reducing energy consumption while enhancing worker comfort.

Conclusion

Though it may seem like just a raw material, cooling pad kraft paper determines the performance of the entire evaporative cooling system. If you’re looking to source cooling pad kraft paper for manufacturing, Golden Paper is a reliable partner. With over 20 years of papermaking expertise, we can supply you with high-quality cooling pad kraft paper on time. Contact us today to start your order!

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id