Introduction

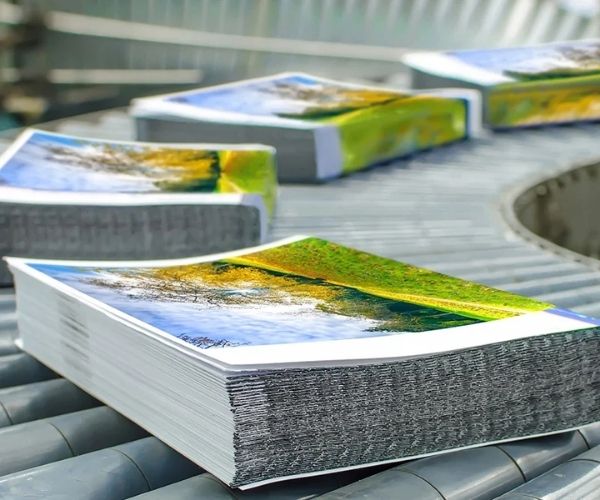

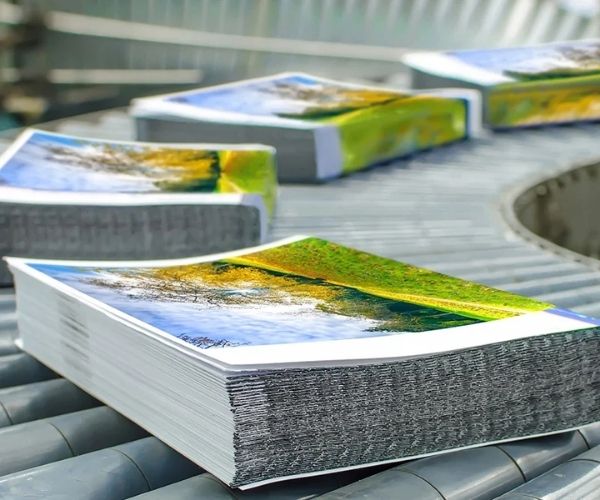

In printing, it’s widely known that paper quality affects the final result. But not everyone knows which paper properties actually determine color reproduction. Differences are noticeable between papers, across batches, and even on the front and back of the same sheet. Surface Efficiency (PSE) is a key concept used to quantify these differences, offering valuable guidance for both the printing and paper industries.

Why Surface Efficiency Matters

Paper properties such as whiteness, hue, gloss, ink absorption, and porosity all affect printability. However, these indicators often give only a qualitative sense of performance and can’t fully measure their combined impact on color reproduction.

Printing professionals often face this problem: using the same ink and settings, different papers show noticeable differences in color intensity, contrast, hue, and gray levels. Sometimes, even the front and back of the same sheet yield inconsistent results. This shows that paper affects ink color in a complex, multifactorial way.

To address this, researchers in the 1960s introduced Paper Surface Efficiency (PSE), a measure to systematically describe how paper influences ink color performance.

The Nature of Surface Efficiency: Non-Optical, Yet Color-Defining

Surface Efficiency is a non-optical property that determines how paper reproduces tonal levels. While color is optical, the final appearance of ink depends not just on the ink itself but also on how the paper surface interacts with it.

Studies show that the two most critical factors are:

Ink absorption – how the paper pulls ink in.

Surface gloss – how reflective and smooth the paper is.

Differences in these two factors explain variations in color intensity, gray balance, hue, and overall color efficiency, which is exactly what PSE measures.

How Ink Absorption and Gloss Affect Color

Ink Absorption

High ink absorption allows ink to penetrate deeper into the paper, reducing pigment on the surface. This can make colors appear lighter, less saturated, and sometimes blur fine details.

Gloss

High-gloss paper reflects more light, making the ink layer appear denser, smoother, and more vibrant. Low-gloss paper tends to produce duller, flatter colors with less contrast.

Combined Effect

Absorption and gloss work together, not separately. Evaluating one without the other won’t fully reflect a paper’s print performance. This is why Surface Efficiency is so valuable.

Calculating Surface Efficiency (PSE)

In 1975, Rabinshy and Emmel proposed the formula:

{PSE (%) = [100 − A (%) + PG (%)] / 2}

Where:

PSE – Paper Surface Efficiency

A – Ink absorption

PG – Paper gloss

Key idea:

Higher absorption reduces color efficiency.

Higher gloss enhances color performance.

By combining both, PSE gives a clear, single measure of how paper will perform in color printing.

Practical Significance of Surface Efficiency

For printers and paper buyers, PSE provides a reliable reference to choose the best paper for high-quality color printing, especially when color stability and tonal accuracy are crucial.

For paper manufacturers, improving PSE means optimizing absorption control and surface treatment, making products more competitive in the premium printing market.

Conclusion

Surface Efficiency bridges paper properties and print color results. By quantifying the effects of ink absorption and surface gloss, it helps ensure consistent, high-quality color reproduction. Understanding and applying PSE benefits printers, designers, and paper suppliers alike. Golden Paper has over 20 years of expertise in professional papermaking. Contact us for samples and quotes to meet your printing needs.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id