Introduction

In the food packaging industry, PE coated paper is one of the most common materials. From disposable cups and lunch boxes to burger wraps and fried chicken bags, it is widely used. As a buyer or procurement manager, you might wonder: Is PE coated paper safe when holding hot drinks or greasy foods? This guide explains its composition, production process, safety features, and applications, helping you make informed sourcing decisions while also meeting sustainability goals.

What Is PE Coated Paper?

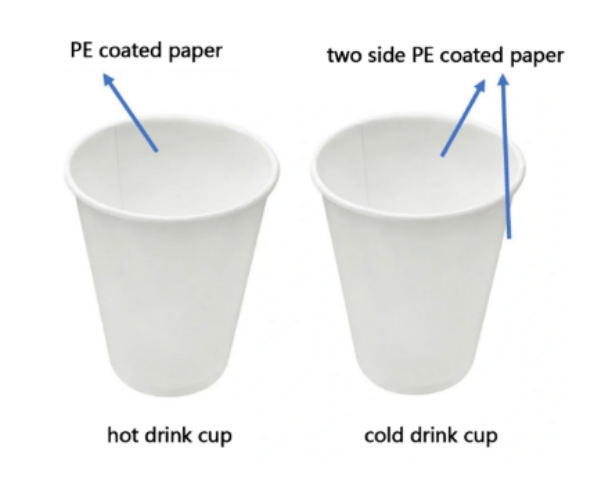

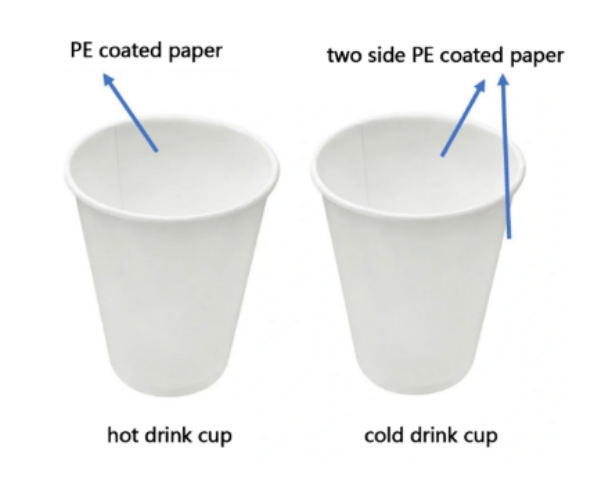

PE coated paper, also known as PE laminated paper, is a composite material made of base paper with a single or double layer of polyethylene (PE) film. The base paper is usually food-grade white paper or kraft paper. After surface treatment, it is coated with PE film through an extrusion process, creating a durable and functional barrier.

The Characteristics of PE Coated Paper

Oil Resistance

The PE layer forms a barrier that prevents oil and grease from seeping through. This keeps the outer packaging clean while maintaining the appearance and taste of the food. It is especially suitable for fast food, baked goods, and high-oil prepared meals.

Water Resistance

While not 100% waterproof, PE coating effectively blocks moisture for a certain period of time. For example, in cold drink cups, takeaway containers, or humid environments, packaging maintains strength and integrity, extending shelf life and improving customer experience.

Heat-Sealable

The PE layer has strong heat-sealing performance, allowing quick and secure sealing at relatively low temperatures. This improves hygiene, enhances packaging integrity, and makes it compatible with automated packaging lines. For food companies producing at scale, this feature reduces costs and boosts overall efficiency.

PE coated paper is widely used in food packaging (burgers, fries, fried chicken, sandwiches, lunch boxes, and even oven-safe papers) and industrial applications requiring oil and moisture protection. Food-grade versions have strict requirements: no fluorescent agents in the paper and pure polyethylene without additives. These products are safe, eco-friendly, and aligned with corporate sustainability strategies.

The Advantages of PE Coated Paper

During production, PE film often undergoes corona treatment for better adhesion and surface uniformity. Key advantages of food-grade PE laminated paper include:

Heat Resistance: Withstands up to 121°C, suitable for hot drinks, lunch boxes, and oven baking paper.

Non-toxic and Odorless: Meets international food contact safety standards, ensuring no harmful substances are released under normal or high temperatures.

Eco-Friendly: Works with water-based printing inks, reduces plastic usage, and supports companies’ green packaging goals.

These features make PE coated paper a safe, efficient, and sustainable choice for food packaging manufacturers and distributors.

Safety Analysis of PE Coated Paper

If you are sourcing wholesale PE coated paper for your business, here are the main safety concerns to consider:

Stability of Food-Grade PE

Polyethylene is a stable plastic with a melting point of 120–130°C. Hot beverages are typically 60–80°C, well within the safe range where PE does not decompose or release harmful substances.

Quality Control of Base Paper and PE Film

Safe PE coated paper requires base paper free of fluorescent agents and PE film made from pure polyethylene. These standards ensure durability, hygiene, and compliance with food packaging requirements.

Regulations and Certifications

Reputable manufacturers supply PE coated paper that complies with national food safety regulations (e.g., SC certification). Buyers should only choose certified products to avoid risks such as harmful inks or excessive additives.

Usage Guidelines

Avoid prolonged storage of liquids above 90°C, as this may accelerate material aging.

Single-use only; repeated use may damage the PE layer.

Always ensure coatings and printing materials meet food contact compliance.

When these standards are met, PE coated paper is both safe and environmentally responsible, reducing plastic waste while helping businesses meet sustainability commitments.

Applications and Buying Guide

Food Packaging Applications

Hot Drink Cups: Strong heat resistance prevents leakage and softening, ensuring a safe and enjoyable coffee or tea experience.

Burger and Fried Chicken Wrapping Paper: Excellent oil and water resistance preserves crispness and cleanliness, widely used by fast-food chains and restaurants.

Lunch Boxes and Oven Paper: Can withstand reheating in microwaves or ovens while maintaining taste and quality.

Industrial Packaging Applications

Moisture-Proof Packaging: Protects paper products, dry goods, and chemicals from water damage during shipping and storage.

Heat-Sealable Material: Compatible with automated production lines, improving efficiency and sealing performance for bulk packaging needs.

Buying Tips for Procurement Managers

When sourcing food-grade PE coated paper, you should pay attention to base paper quality, PE film thickness, heat-sealing performance, and certification or compliance marks. By focusing on these factors and working with the right supplier, you can ensure packaging that is safe, efficient, and cost-effective for your business.

Conclusion

For food packaging companies, PE coated paper is a safe, eco-friendly, and practical material. By sourcing certified products and following proper usage, you can avoid health risks while meeting functional needs such as oil resistance, water resistance, and heat tolerance. At the same time, it helps reduce reliance on plastics and supports your company’s sustainable packaging strategy. From disposable coffee cups to burger wraps and lunch boxes, PE coated paper is an ideal solution for modern food packaging manufacturers, suppliers, and distributors. Contact Golden Paper for quote now!

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id