Introduction

In gift box manufacturing, the quality of the outer packaging paper plays a crucial role in determining both the visual appeal and processing efficiency of the final product. Many buyers focus mainly on the grammage and price of the paper, but in reality, factors like flatness, curl resistance, and adaptability to processing are what truly impact yield and production stability. In this guide, we'll walk you through four key factors—moisture content, grammage, coating type, and lamination process—to help you choose the right paper supplier for your gift box packaging needs.

Choosing the Right Paper for Box Packaging

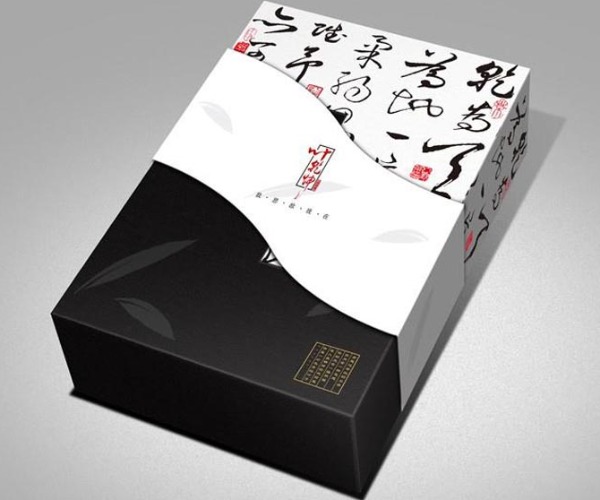

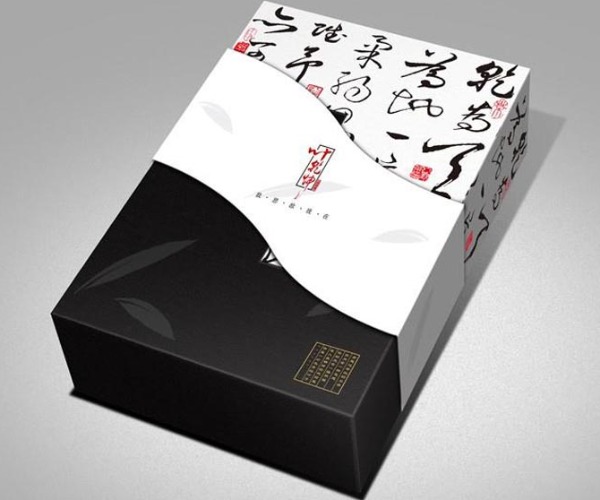

Gift boxes often have a complex structure that includes a greyboard core and several functional parts such as outer wrap, edge lining, inner lining, top insert, side flaps, and ribbon handles. To enhance the visual appeal, coated art paper in 128gsm, 157gsm, or 200gsm is commonly used for printing the outer layers.

However, if this paper curls during processing, it can cause serious issues—misalignment during printing, poor gluing results, or even complete bonding failures. These problems reduce productivity and increase material waste.

To avoid these issues, it's essential to test each batch of coated paper before use. Key performance indicators include moisture content, smoothness, gloss, coating strength, absorbency, and drying properties. Only paper that meets process compatibility requirements should move forward to production.

What Causes Paper Curling?

Paper Moisture Content

Although coated paper is relatively stable and smooth when shipped, it can absorb or release moisture depending on environmental humidity. This is the leading cause of paper curling.

If the surrounding humidity exceeds the paper's equilibrium moisture level, it absorbs moisture—typically more from one side—causing it to curl in the opposite direction.

Conversely, in low humidity environments, the paper loses moisture, and the side that loses more will curl toward the moister side.

This problem is especially common during southern China's rainy season or the dry winters in northern regions.

Best Practice: Keep the production and storage environment within ±5% of the paper's equilibrium humidity. Avoid exposing the paper to extreme climates. For regions with large humidity fluctuations, consider installing a temperature and humidity-controlled storage area or allow the paper to acclimate before use.

GSM (Grammage) of the Paper

The grammage of the paper (gsm) not only affects thickness but also its resistance to environmental changes. Heavier paper (like 157gsm or 200gsm) is thicker, has denser fiber structure, and more balanced surface tension—making it less likely to curl.

In contrast, lighter papers such as 128gsm are more vulnerable to moisture and adhesive penetration. During gluing, adhesives can easily seep into thin paper, causing one side to swell, resulting in edge lifting and bubbling.

Recommendation:

For small boxes: 128gsm art paper is suitable.

For larger boxes: use 157gsm or heavier, or consider structurally stable textured or specialty paper.

Single vs. Double-Sided Coating

Coated paper comes in single-sided or double-sided variants. Double-sided coated paper has even coating on both sides, which balances internal stress and keeps the sheet flat during processing.

However, single-sided coated paper has only one coated side—the uncoated side is more porous and absorbs moisture more quickly. In humid conditions, this causes the paper to curl toward the coated side.

For gift box outer wrapping, we strongly advise against using single-coated paper, especially in regions with high humidity. If it must be used, conduct pre-production testing and ensure proper humidity control during manufacturing.

Paper Lamination Process

High-end gift boxes often use metallic or pearl finishes through laminated coated paper. This involves bonding a thin film (like silver foil) to the printed surface using UV printing techniques, creating a mirror-like or textured effect.

However, laminated paper has a moisture imbalance: the front side is sealed with film and doesn't absorb moisture, while the exposed back side does. This difference leads to curling toward the laminated side—especially in humid climates.

Solution: Apply a back coating treatment on the unlaminated side to create a similar moisture barrier. Based on our factory experience, a 3gsm back coating strikes a good balance between moisture resistance and stiffness.

This improved laminated structure significantly reduces curling and enhances flatness and friction resistance during printing and gluing.

Conclusion

At Golden Paper, we specialize in supplying coated art paper, grayboard, and other packaging paper materials to gift box manufacturers. A great paper makes a great box—and with the right knowledge, you can avoid costly mistakes caused by poor curl resistance or process mismatch. We hope this guide helps you in making informed decisions when sourcing wrapping paper for gift boxes. For product samples, process consultation, or custom orders, feel free to contact us anytime.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id