Introduction

Whether you work in printing, packaging, or just use paper every day, you probably rely on high-quality paper products. But have you ever wondered how trees are transformed into smooth, white sheets? Let's break down the paper-making process step by step. Understanding how paper is produced can help you make smarter purchasing decisions.

The Paper-Making Process: Step by Step

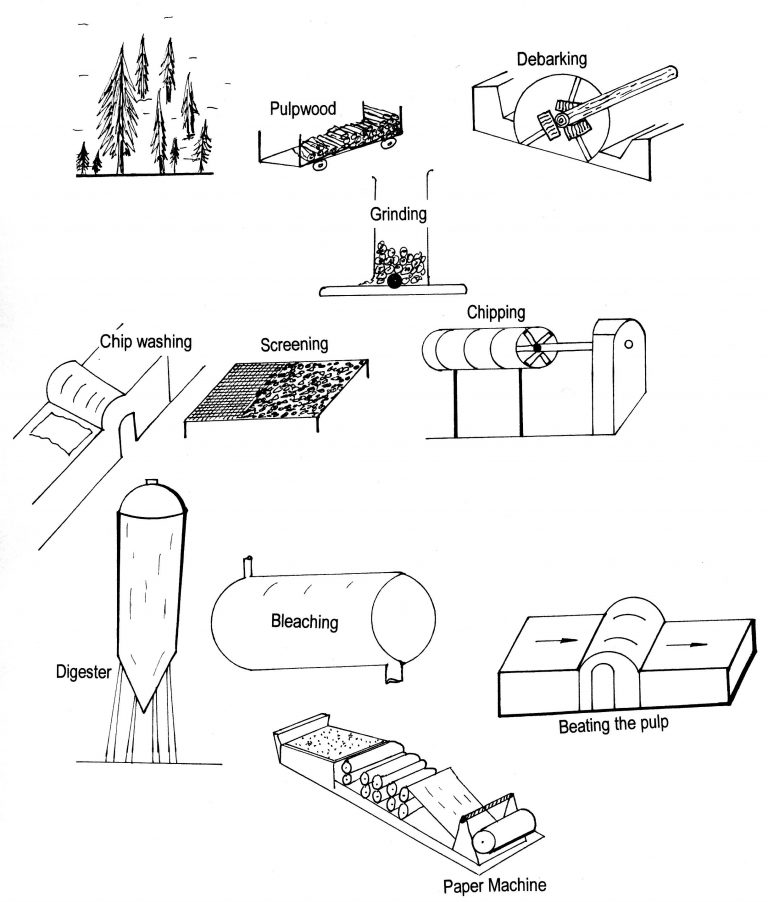

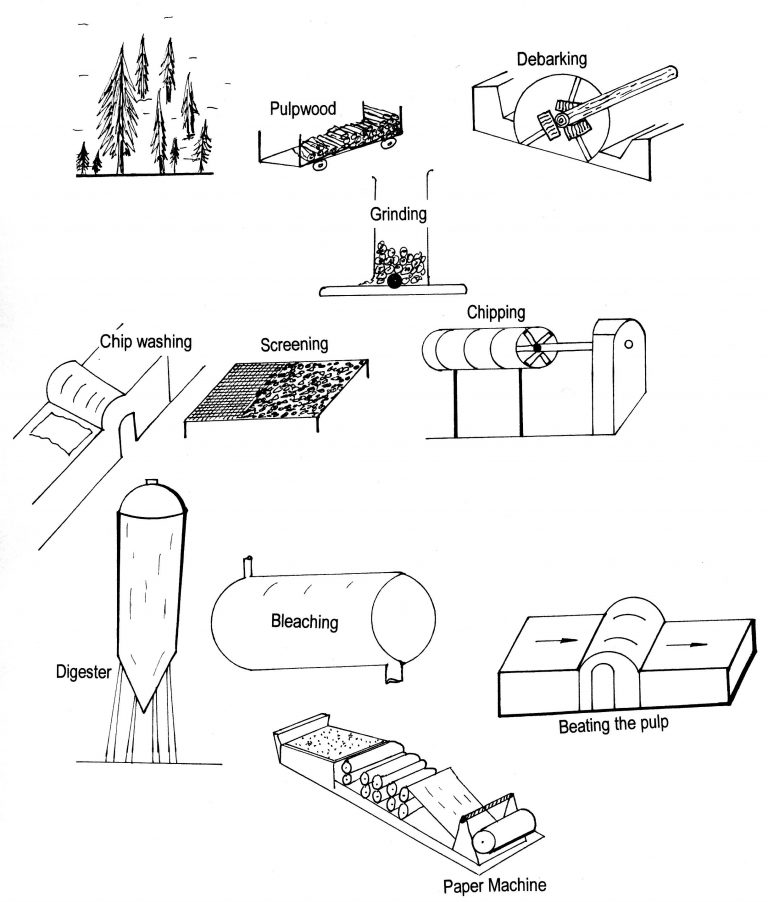

Pulping: Turning Wood into Fiber

The journey of paper starts in the forest. Paper mills typically use fast-growing trees like pine or eucalyptus, which are ideal for paper production. Once harvested, the logs are transported to the mill, where they are debarked and chipped into small, uniform pieces.

Next comes chemical pulping: the wood chips are cooked in a large digester with alkaline solutions (like sodium hydroxide and sodium sulfide) under high heat and pressure. This breaks down lignin—the natural "glue" that holds wood fibers together—leaving behind cellulose and hemicellulose, the essential components of paper.

The leftover liquid, called black liquor, contains dissolved lignin and chemicals. Instead of wasting it, mills recover and reuse it—evaporating the liquid, burning it in a recovery boiler, and generating energy to power the mill. This makes paper production more sustainable by recycling both chemicals and energy.

Refining: Enhancing Paper Pulp Quality

Raw pulp isn't ready for papermaking yet—it needs refining. First, the pulp is screened to remove impurities like dirt or unprocessed wood fragments. Then, it goes through beating/refining, where mechanical processes roughen the fibers, increasing their surface area and flexibility. This step determines key paper qualities like strength, smoothness, and printability.

Finally, additives are mixed in based on the type of paper being made: Fillers (like clay or calcium carbonate) improve opacity and brightness. Sizing agents control ink absorption. Dyes adjust color.

Think of this stage like cooking—the right mix of ingredients determines the final product's performance.

Papermaking: Forming Sheets from Pulp

The refined pulp is fed into a paper machine, where it undergoes several stages:

Forming Section: The diluted pulp (99% water!) is spread onto a moving mesh screen. Water drains away, and fibers bond into a thin, wet sheet.

Pressing Section: Rollers squeeze out more water and compact the fibers for better strength.

Drying Section: The sheet passes over heated cylinders, evaporating remaining moisture. Hydrogen bonds form between fibers, making the paper stable and strong.

Calendering: Hot steel rollers smooth and polish the surface for better print quality.

The finished paper is wound into giant rolls (called jumbo reels) for further processing.

Converting: Turning Paper Rolls into Usable Products

Before reaching customers, paper rolls go through finishing steps:

Slitting & Rewinding: Large rolls are cut into smaller, custom widths.

Sheeting: Rolls are trimmed into standard sizes (like letter or A4).

Packaging: Paper is wrapped in moisture-resistant materials, labeled, and prepared for shipping.

Conclusion

Now you know how trees become the high-quality paper you use every day. At Golden Paper, we follow strict manufacturing standards and use advanced technology to deliver top-tier paper products. If you're looking for a reliable paper supplier, contact us today—let's start a successful partnership!

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id