Introduction

Choosing the right type of paperboard is essential for protecting your products, improving transportation efficiency, and enhancing your brand image. Corrugated paper and chipboard are two of the most popular paper-based packaging materials, but they differ greatly in structure, performance, and applications. In this guide, you'll learn the key differences between corrugated paper and chipboard, so you can make an informed decision for your packaging needs.

Definition

Corrugated paperboard is a composite material made by bonding linerboard (outer and inner sheets) with fluted corrugated medium (also called fluting paper). The fluted structure is created by processing paper through corrugating rollers, giving the board excellent compression strength and cushioning properties. Corrugated board comes in various structures—single face, single wall (3-ply), double wall (5-ply), triple wall (7-ply), or even 11-ply—depending on packaging requirements. Its basic structure consists of linerboard, corrugated medium, and back liner, forming a lightweight yet strong packaging material.

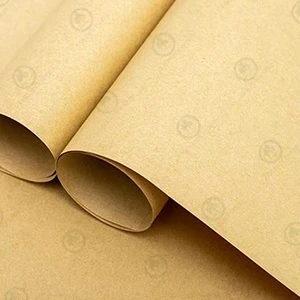

Chipboard—also known as greyboard—is made by laminating multiple layers of recycled paper pulp, with a gray or gray-brown inner core that increases stiffness and strength. Its surface is smooth and uniform in color. Chipboard is manufactured using high-quality pulp and multiple pressing processes, giving it excellent rigidity, stiffness, and dimensional stability. The smooth surface makes it ideal for various printing and lamination techniques, commonly used for luxury gift boxes, book covers, and internal support for folders.

Difference Between Corrugated Paper and Chipboard

Characteristics

Corrugated Paper

Corrugated paper offers a low cost, flexible processing, and high strength solution. It can be made from hardwood pulp or recycled waste paper, which keeps production costs down. Although corrugated board is thick, its hollow structure makes it lightweight, reducing shipping costs. Corrugated board can be processed through die cutting, gluing, and printing to fit various shapes and sizes. The fluted structure provides superior compression resistance and cushioning to protect goods during shipping. The surface is compatible with various printing techniques, supporting brand marketing and aesthetic packaging. Additionally, corrugated board is compact and easy to store, improving logistics efficiency.

Chipboard

Chipboard features a uniform gray or gray-brown color and a smooth, fine surface ideal for printing and lamination. It has excellent stiffness and does not bend easily, providing stable support for products or packaging. Chipboard is pressed under high temperature, giving it strong tensile strength to withstand pressure and tension, protecting items inside. Its outstanding bending resistance makes it suitable for packaging that requires frequent opening and closing, such as folders and file boxes. Chipboard maintains dimensional stability across different environmental conditions. It is also eco-friendly, made from recycled paper, and can be recycled again, contributing to the circular economy. Compared to premium wood-based boards, chipboard is more affordable and offers excellent value for budget-conscious industries.

Long-tail keywords: recycled chipboard packaging, eco-friendly chipboard board, chipboard vs cardboard.

Uses

Corrugated Paper

Corrugated paper is used extensively in logistics and transportation, exhibition displays, home furniture, and advertising signage.

Packaging: It is one of the most common materials for shipping containers, used in industries such as food, beverages, consumer goods, electronics, appliances, and furniture (e.g., shipping boxes, beer cartons, and heavy-duty packaging).

Exhibition displays: Corrugated board is used to create cost-effective, reusable display racks, display boards, and exhibition booths that are easy to transport and install.

Home furniture: Some furniture packaging, display racks, and storage boxes are made with corrugated paper, offering both eco-friendliness and cost savings.

Advertising signage: Corrugated board can also be used to create signs and point-of-sale displays with strong visual appeal and durability.

Chipboard

Chipboard is mainly used in luxury packaging, electronics packaging, stationery products, home decor, and other functional applications.

Luxury packaging: Chipboard is used for packaging high-end products like cosmetics, jewelry, tea, mooncakes, wine, and craft gifts, offering excellent structural support and a premium appearance.

Electronics packaging: Chipboard is used for phone, laptop, and camera packaging, providing the necessary strength and cushioning to protect products during transit.

Stationery: It is used to make durable file folders, hardcover book covers, and photo album covers, enhancing product durability and appearance.

Home decor: Chipboard is commonly used for photo frame backing boards, storage boxes, and even TV wall panels due to its smooth surface and eco-friendly properties.

Other applications: Chipboard can also be made into advertising display boards, poster boards, and paper tubes for various industrial and packaging purposes.

Conclusion

Both corrugated paper and chipboard serve important roles in the packaging industry. Corrugated paper is preferred for its high strength, cushioning properties, and easy transport, making it ideal for shipping and logistics. Chipboard is valued for its excellent stiffness, premium appearance, and eco-friendly profile, making it ideal for luxury packaging and stationery products. Choosing the right material depends on your product features, packaging needs, and budget.

At Golden Paper, we provide high-quality corrugated liner paper and grey chipboard, customized to meet your packaging requirements. Contact us today to enhance your packaging solutions with sustainable, efficient materials!

FAQ

Q1: Which is more eco-friendly, corrugated paper or chipboard?

Both materials are eco-friendly and primarily made from recycled paper. However, chipboard typically contains a higher percentage of recycled content, promoting further resource recycling.

Q2: Can chipboard be used for shipping packaging?

Chipboard is mainly used for lightweight and high-end packaging and lacks the shock absorption needed for heavy-duty transport. For long-distance or rough handling, corrugated board or a composite structure is recommended.

Q3: Is corrugated paper suitable for high-end printed packaging?

Corrugated board can be printed with graphics and text, making it suitable for brand marketing. However, for extremely smooth or luxury packaging, chipboard is better suited for premium printing, foiling, and lamination techniques.

Q4: Which material is easier to store?

Chipboard is thinner and stackable, taking up less storage space—ideal for space-constrained warehouses. Corrugated board, due to its fluted structure, requires more storage space.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id

.webp)